Vehicle Technology Assessment Workflow

Systematically quantify vehicle technology impacts on energy consumption, performance and cost, including uncertainties.

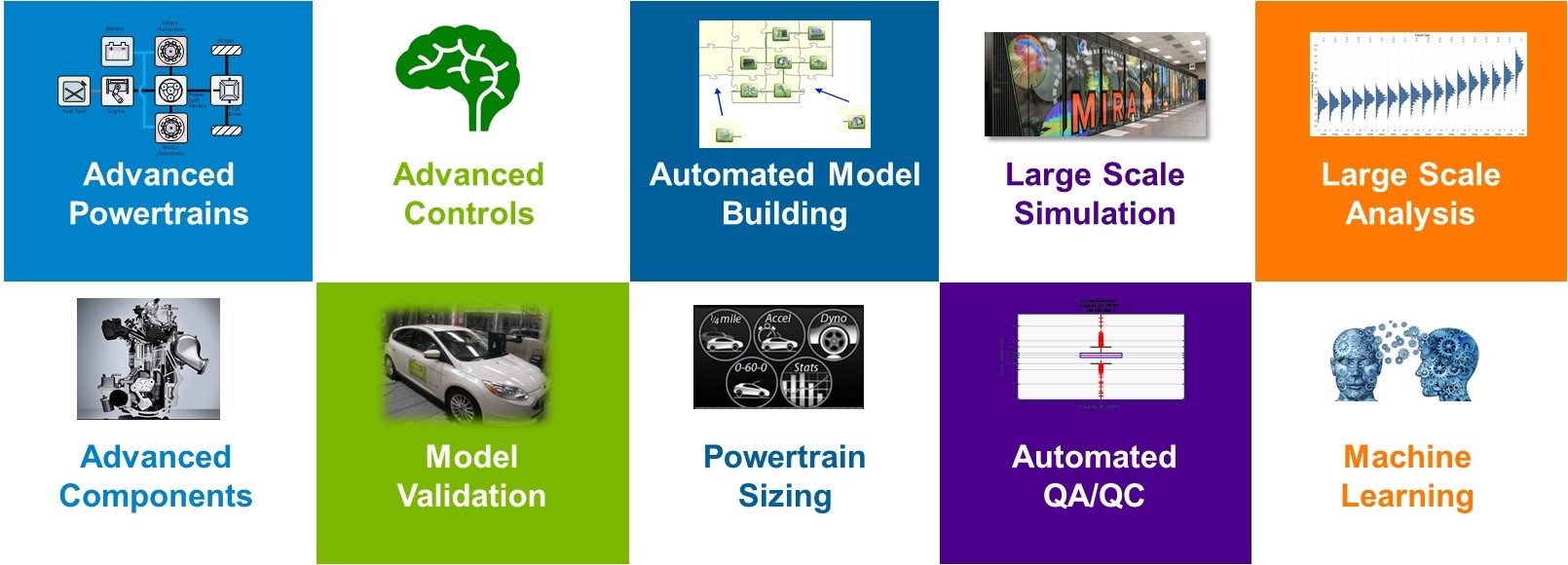

Increased vehicle and powertrain technology options have heightened the reliance on system simulations to assess energy consumption, performance, and cost. The vast number of vehicle classes, powertrain options, component technologies, and vehicle technical specifications (VTS) make for a dizzying array of potential vehicle designs. Over the past 20 years, the Argonne National Laboratory Vehicle & Mobility Systems Group (VMS) has developed an automated end-to-end workflow that assesses the impact of these technologies, including:

- Advanced powertrains: all designs currently in production or planned, including conventional, start-stop, hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), battery electric vehicles (BEVs), and fuel cell electric vehicles (FCEVs);

- Advanced components: performance data for any current and future technologies, including transmission types, gear number/ratios, and more than 25 different engine technologies;

- Advanced controls: control algorithms and calibration developed from individual vehicle dynamometer testing (see sample data in our Downloadable Dynamometer Database);

- Automated model building with millions of possible design options; and

- Powertrain sizing: automatically sized components to meet the vehicle technical specifications (VTS).

All simulations can be launched in high-performance computing (HPC) and perform automatic quality assurance/quality control and analysis. Additionally, you can use Autonomie, Argonne’s state-of-the-art vehicle energy consumption, performance, and cost system simulation tool, for individual vehicle simulation outputs to develop machine learning models.